Facility Overview

The customer is a high-volume poultry packaging facility operating in a competitive, energy-intensive environment. As part of a broader corporate initiative, the facility is aggressively pursuing sustainability goals, including reducing energy consumption and lowering its overall carbon footprint.

Recent additions of processing equipment increased compressed air demand across the plant, creating pressure stability challenges and rising energy costs.

The Challenge

Rising Demand and Inefficient Pressure Management

As new processing equipment was installed, one specific machine required higher air pressure than the rest of the plant. To address this, the system pressure was increased across the entire compressed air network.

This approach created several issues:

- Increased energy consumption due to elevated system pressure

- Higher operating costs across all air users, not just the critical equipment

- Misalignment with the customer’s sustainability and ROI objectives

The initial internal concept was to install a point-of-use air receiver to support the high-demand equipment while maintaining an ROI of less than two years. Before making any capital investment, the customer engaged Rasmussen Air & Gas Energy to conduct a comprehensive evaluation of the compressed air system and identify the most effective solution.

The Solution

System Assessment and Data Collection

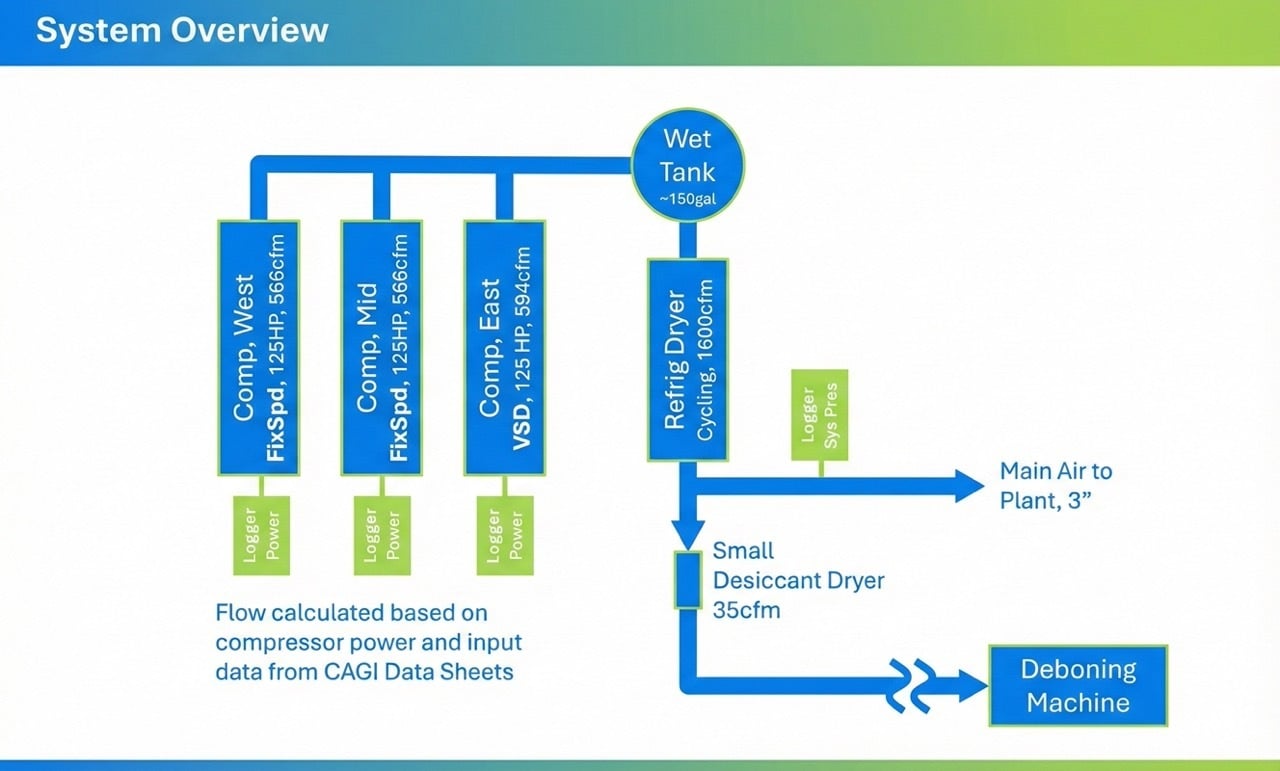

Rasmussen Air & Gas Energy installed temporary monitoring equipment on the industrial compressed air system and collected operational data over a one-week period.

Existing Compressor Configuration During the Audit

Two compressors were available to operate, with a third installed but not required during the monitoring period.

- Compressor “B”

- Fixed Speed Load/Unload compressor

- Primary contributor supplying air to the system

- Compressor “A”

- Variable Speed Drive (VSD) compressor

- Intended to support system demand, but rarely contributed to airflow

Key Findings from Trend Data

During the audit of the compressed air systems several key findings were found:

- Every time the Fixed Speed compressor loaded, the VSD compressor would start

- The system demand was satisfied before the VSD could ramp up and contribute meaningful airflow

- The VSD compressor would then shut down without providing value

- Both compressors were operating at the same pressure setpoints, causing them to effectively “fight each other”

This operating behavior led to unnecessary startups, inefficient load profiles, and preventable energy consumption.

The Recommendation

Rather than adding equipment, Rasmussen Air & Gas Energy recommended a control-based optimization strategy.

Strategic Setpoint Staggering

- The VSD compressor was designated as the Trim Compressor

- Pressure setpoints were staggered so the VSD unit responds first to plant demand

- The Fixed Speed compressor only engages when system demand exceeds the VSD’s efficient operating range

This configuration allows:

- The VSD compressor to handle normal and fluctuating demand efficiently

- Elimination of short cycling and unproductive starts

- Reduced system pressure without sacrificing production reliability

Importantly, the audit data confirmed that the VSD compressor alone was capable of satisfying the plant’s full air demand during normal operation.

The Results

Measurable Energy and Cost Savings

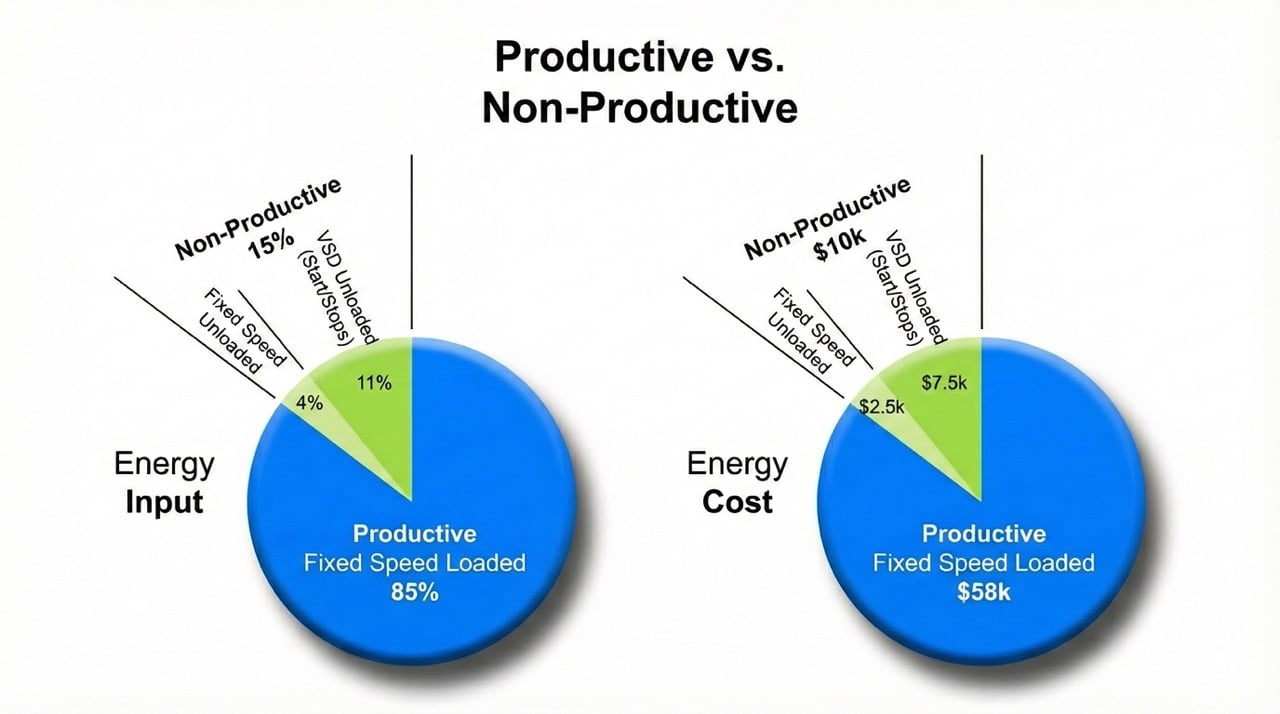

By implementing strategic setpoint staggering:

-

Energy consumption for the compressed air system was reduced by 14%

-

Unproductive compressor operation was eliminated

-

System stability improved without additional capital equipment

-

ROI was achieved in less than 9 months

This solution directly supported the customer’s sustainability goals while promptly delivering measurable financial returns.

Why This Matters

This project demonstrates that compressed air optimization does not always require new equipment. In many cases, data-driven control strategies can lead to significant savings, enhance compressed air system reliability, and reduce environmental impacts.

For facilities experiencing increased air demand, expanding production, or sustainability pressures, system analytics and intelligent compressor control can provide a faster return on investment than traditional hardware-focused approaches.

Rasmussen Air & Gas Energy’s Role

For this project Rasmussen Air & Gas Energy provided:

- System-level compressed air monitoring and data analysis

- Engineering-driven recommendations based on actual operating behavior

- Practical compressed air solutions aligned with both energy efficiency and production requirements